Solutions

ICDSolution’s manufacture support offer solutions that are designed to enable clients to lower costs of IC manufacture, enhance time to market, and improve profitability by addressing design and manufacturing interactions from initial process ramps to mature manufacturing operations.

The manufacture support package provides the bridge between research and production by implementing methodology and standardization. Enable clients to reduce time-to-market and time-to-revenue for their products

- PCM methodology

- SPC methodology

- Yield Enhancement

- device model

- IP libraries

- design rules

- DFM

- i-Flow

- i-MES

- full ERP

- i-Data

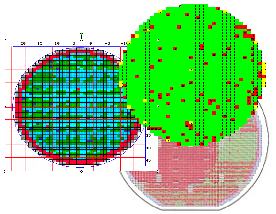

Yield enhancement (YE) methodology

In the hyper-competitive world of semiconductor manufacturing, yield improvements are keys to increase manufacturing productivity and profitability,

ICDS’s yield enhancement strategy combine PCM, SPC and integration engineering services to provide clients new fab yield management solution planning; factory and field customer applications training; dedicated ramp management support; integrated yield management consulting/applications and remote-access diagnostics.

With ICDS’ proven methodology for process-design integration target yield and reliability improvement, our approach consists of three essential elements:

- Characterization: Comprehensive investigation of PCM and SPC data to identify the yield limitations for a broad set of fundamental design elements, and the effects of process variations on circuit performance.

Process Control Monitor (PCM) methodology

The methodology for developing the IC in the industry is completely standardized. To reduce the learning curve we do not need to reinvent the wheel but spending the valuable time on improving existing technology

PCM includes most basic test structures such as typical transistors, diodes, sheet resistance, comb isolations, contact chains, capacitances (junction, oxide and finger), passive devices (inductor, MIS, MIM…) and RF test.

By applying the proven methodology, certain guidelines must be followed such as layout standardization, TC standardization, design rule standardization, PCM module standardization. ICDSolution PCM methodology includes standardization guidelines for layout, TC, design rule, and PCM module

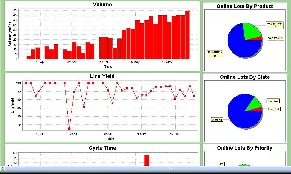

Statistics Process Control (SPC) methodology

SPC provided the tool for analysing manufacturing processes, and exploring opportunities through designed experiments. It is integrated seamless real-time with ICDS’s MES environment I-Flow from data input to report generation.

It Bridges between research and production by implementing methodology and standardization. Enable clients to reduce time-to-market and time-to-revenue for their products

ICDSolution not only supply software itself, but also help clients to set up SPC parameters and define SPC control target, which is backed by in-depth knowledge for semiconductor process, device, reliability and yield.

ICDSolution provides the effective way for manufactures to reduce time-to-market and time-to-volume, which is the key to increase profitability.

- ICDS view data analysis as a powerful technique to be used in combination with statistical process control and design of experiments. We also deal with the precautions that are necessary to prevent drawing false conclusions from data analysis.

- Prioritizations: Focus on the most important yield issues based on an analysis of yield-loss components by process module,,defect type, device and product performance. Then propose to make process more amendable to design and/or to make design to less sensitive to critical manufacturing steps and controls.

Your partner in semiconductor production